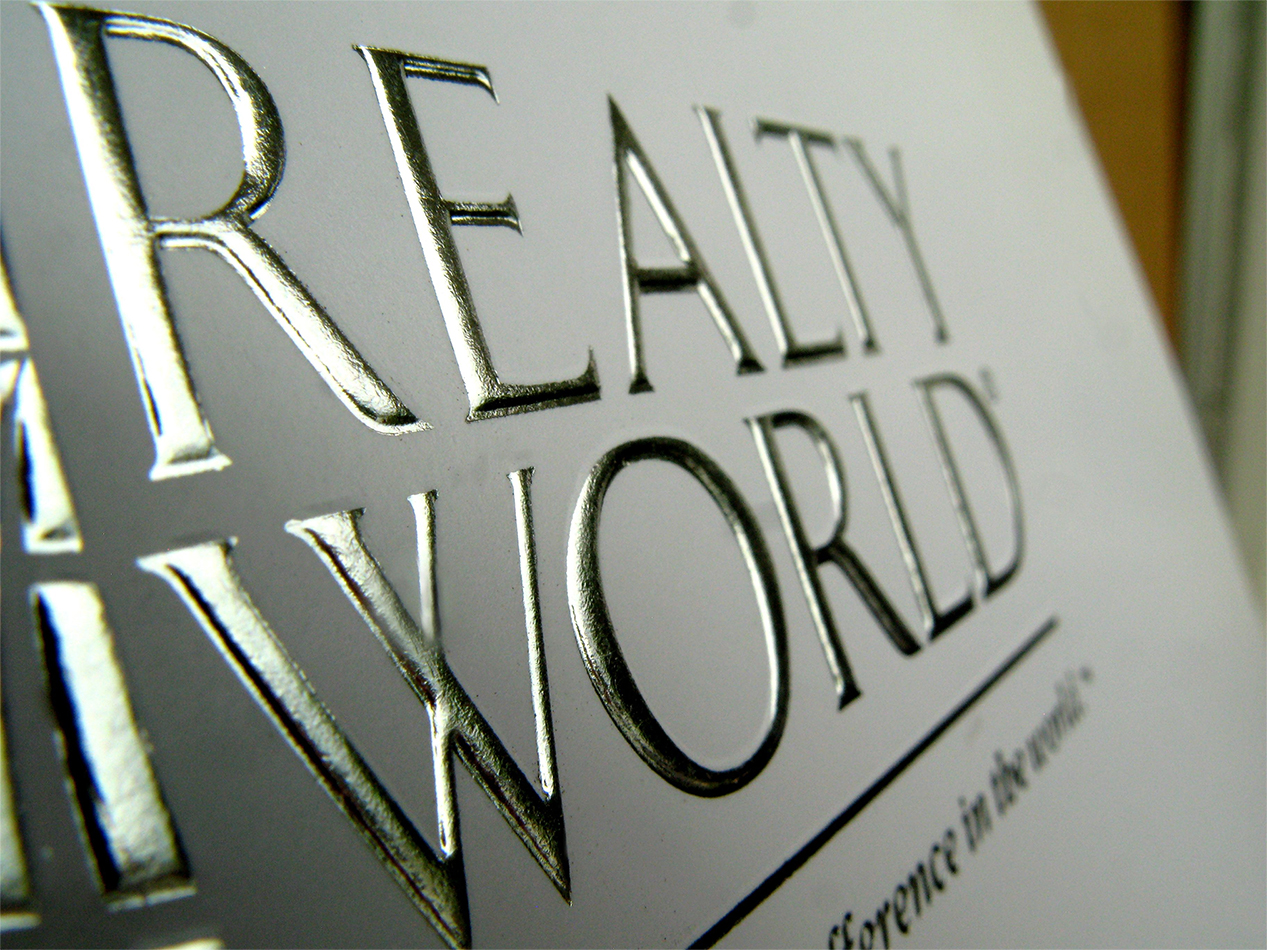

Emboss Print

Emboss printing, the advantage of emboss printing is that it gives a different and luxurious look to your print. For example, in the printing of door covers, wallpapers, wall coverings, and wooden, plastic, paper products, etc., the use of embossing for the protrusions will attract more attention due to the luxurious appearance.

Embossing is one of the printing methods in which a template with the desired design is pressed on the surface of paper or other materials that you intend to print on. With this process, a three-dimensional design is formed on the surface of the desired paper or material, and by this method, various designs can be printed on the surface with a three-dimensional appearance.

Emboss Print

In emboss printing, two types of formats are used. Deep molds or molds with less prominence. Deeper dies create more drastic changes to the surface of the paper or material, and shallower dies are usually used to create smaller designs and finer details.

The advantage of emboss printing

This is what gives your print a different and luxurious look. For example, in the printing of door covers, wallpapers, wall coverings, and wooden, plastic, paper products, etc., the use of embossing for the protrusions will attract more attention due to the luxurious appearance.

Also, emboss printing is used for other products such as brochures, business cards, book covers, postcards, etc. In any case, to create high quality and luxury emboss printing, it is necessary to use quality equipment and materials. To create the required format in emboss printing, you can use specialist printers or companies that provide these services. Alternatively, you can use tools such as die-cuts, embossing strips or polymer materials to create a template.

پ

پ

In emboss printing, there is no need to use ink or paint, and only by creating pressure on the surface of the desired paper or material, a three-dimensional design is created. For this reason, this method is very suitable for printing luxury and rare products, such as high-quality business cards, invitations and brochures.

However, it should be noted that emboss printing has limitations compared to other printing methods, such as digital printing. For example, you cannot create a multi-color print using embossing. Also, creating embossing requires the use of separate dies for each design, which can be costly.

Overall, emboss printing is still used in many industries because of its age and also because of its advantages.

In addition to the printing industry, emboss printing is also used in many other industries. For example, in the electronics manufacturing industry, embossing is used to print electronic devices and printed circuit boards. Also, in the automotive industry, embossing is used to print on automotive parts, such as license plates, safety signs, and parts labels.

Emboss printing in the production of PVC coating

Emboss printing is one of the printing methods that is also used in the production of PVC coating. PVC coating is a type of glossy or matte film that is used to cover different surfaces. This coating is usually installed on furniture, doors and windows, cabinet surfaces or other internal surfaces of the home and work environments.

Emboss printing is done in the production of PVC coating because of its advantages. One of these advantages is the possibility of printing on different surfaces with different dimensions. Also, emboss printing can be used for printing on non-smooth and uneven surfaces.

To carry out emboss printing in the production of PVC cover, first a stamp is prepared, which includes the image or design that you want to print on the cover. Then, the PVC coating is placed on the surface and the printing mold is placed on the coating. After the printing plate is placed on the coating, the ink is transferred from the printing plate to the coating using pressure. Then, the coating is completely dried at the appropriate temperature and is ready to use.

In general, emboss printing in the production of PVC coating has some advantages and disadvantages. The main advantage of emboss printing in the production of PVC coating is the ability to print on irregular and non-smooth surfaces, which is limited to this limit in digital printing. Also, by using emboss printing, you can use more diverse colors and, as a result, expand the color range of PVC covers.

In contrast, emboss printing is more expensive than digital printing and has limitations for multi-color printing. Also, due to the use of a printing mold, the production time of PVC cover with emboss printing is longer.

Finally, to choose the right printing method for the production of PVC coating, you should examine your needs and make a decision based on the advantages and disadvantages of each. Emboss printing is known as a valid printing method in the production of PVC coatings due to its ability to print on non-smooth surfaces and high resistance.

To do emboss printing on PVC covers, it is better to contact Rose Film’s sales unit and print your design on the desired cover by creating a suitable template.